EPDM Rubber Footrest Cover For Motorcycle

Overview

Keywords :

Automotive Engine Parts / Rubber Engine Parts / Car Rubber Engine Parts

- Hits : 329

- Company : Xiamen Kingtom Rubber & Plastic Co.,Ltd.

- Telephone : +86-139-5922-6689

Product Description

Five Advantages Of Products

- Vibration Isolation and Noise Reduction: Automotive engine rubber parts effectively absorb engine vibrations, reducing noise and providing a smoother driving experience. This enhances passenger comfort and minimizes wear and tear on other engine components.

- Excellent Sealing Performance: These rubber parts offer exceptional sealing capabilities, creating airtight connections between engine components and preventing leaks. This contributes to improved fuel efficiency, reduced emissions, and a more environmentally friendly driving experience.

- Heat and Chemical Resistance: Automotive engine rubber parts exhibit excellent heat and chemical resistance. They can withstand extreme temperatures and harsh conditions within the engine compartment, ensuring long-lasting durability and reliability. This results in reduced maintenance costs and increased vehicle lifespan.

- Customizability: The versatility of rubber allows for the production of custom-engineered parts tailored to specific engine requirements. Manufacturers can develop innovative designs and optimize performance for various engine configurations, enhancing overall efficiency and performance.

- Promising Prospects: With the ongoing demand for fuel-efficient and environmentally friendly vehicles, the automotive engine rubber parts industry has promising prospects. These components play a vital role in improving overall vehicle performance, durability, and sustainability. Additionally, the rise of electric vehicles presents new opportunities as rubber parts contribute to the efficient operation and longevity of electric motors and battery systems.

Product Details

Automotive Engine Rubber Parts offer several advantages and promising prospects in the automotive industry. These components, made from high-quality rubber materials, play a crucial role in engine performance and overall vehicle reliability.

Firstly, these rubber parts provide excellent vibration isolation and damping capabilities. They effectively absorb engine vibrations, reducing noise and ensuring a smoother driving experience. This improves passenger comfort and reduces wear and tear on other engine components.

Secondly, automotive engine rubber parts offer exceptional sealing properties. They create airtight connections between various engine components, preventing leaks and maintaining optimal pressure levels. This helps enhance fuel efficiency and reduces emissions, contributing to a more eco-friendly and sustainable driving experience.

Furthermore, these rubber components exhibit excellent heat and chemical resistance. They can withstand the extreme temperatures and harsh conditions within the engine compartment, ensuring long-lasting durability and reliability. This results in reduced maintenance costs and increased vehicle lifespan.

Additionally, the versatility of rubber allows for the production of custom-engineered parts, tailored to specific engine requirements. Manufacturers can develop innovative designs and optimize performance for various engine configurations, enhancing overall efficiency and performance.

Looking ahead, the automotive engine rubber parts industry is expected to grow rapidly. The increasing demand for fuel-efficient and environmentally friendly vehicles drives the need for advanced engine technologies. As a vital component in these engines, rubber parts will continue to play a crucial role in improving overall vehicle performance, durability, and sustainability.

Moreover, the rise of electric vehicles presents new opportunities for rubber parts manufacturers. As electric powertrains become more prevalent, there is a growing demand for rubber components that contribute to the efficient operation and longevity of electric motors and battery systems.

In conclusion, automotive engine rubber parts offer advantages such as vibration isolation, sealing properties, heat and chemical resistance, and customization capabilities. With the ongoing evolution of the automotive industry towards greater efficiency and sustainability, these components have a promising future as integral components in modern engines, both traditional and electric.

Experience: More than 20 years experience in rubber OEM production

Shape: According to customer's drawing

Package: PE bags, Cartons,Pallet

Payment Terms: T/T,L/C and so on.

Sample time: 25-30 days

Shipment Way: Vessel,Air,Express etc.

Below is our cooperated car brands for your reference.

Q1.Which kind of product do you produce?

Kingtom:Rubber injection parts,rubber compression parts and rubber extrusion parts,rubber-metal parts,plastic parts.

Q2.What information do you need for making price?

Kingtom:1.2D/3D drawing,or samples photo with detail size.

2.Material And Material hardness

3.Detail quantity

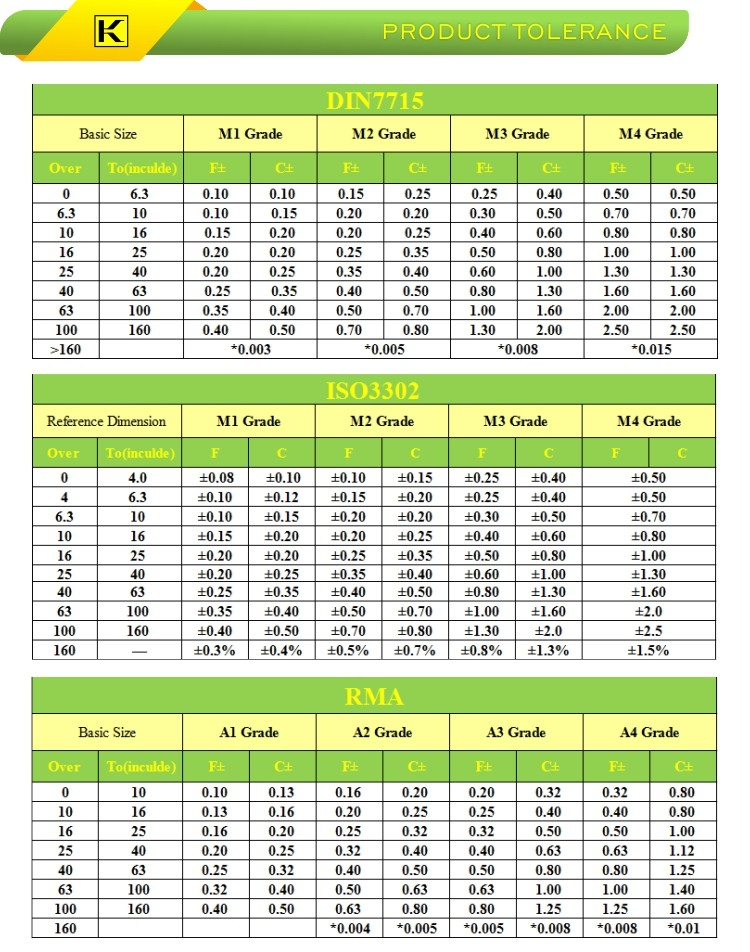

4.Your other requirements like tolerence,surface treatment.

5.Product usage environment

Q3.I don't have 3D drawing,how should i do ?

Kingtom:You can send one sample to us,then we can produce as your sample.

Q4:How to make sure the quality?

Kingtom:Check the samples before mass production.

There is the detail inspection report and goods photos before shipping.

Q5.Do you provide samples?

Kingtom:Yes,samples is free and you just pay the express cost.

Q6.How is the delivery time?

Kingtom:It usually takes 10-30days.It depends on the orders.