Exploring the Different Types of Rubber Seals and Their Properties

Overview

Keywords :

Rubber Products / Rubber Sealing / Rubber Extrusion

- Hits : 336

- Company : Xiamen Kingtom Rubber & Plastic Co.,Ltd.

- Telephone : +86-139-5922-6689

Product Description

Five Advantages Of Products

- High strength and durability: The EPDM rubber material used in the core has a high tensile strength and wears well over time. The soft foam rubber surrounding the core adds comfort and stability, while the black rubber seal provides a water-resistant finish.

- Improved comfort: The soft foam rubber provides a plush, comfortable ride, reducing discomfort caused by harsh impacts and vibrations.

- Improved grip: The black rubber seal improves traction and grip, making the tire more resistant to slippage and instability in adverse conditions.

- Improved fuel efficiency: The EPDM with metal core and soft foam rubber reduce weight and improve fuel efficiency, reducing operating costs.

- Long-lasting quality: The EPDM material used in the core is of high quality and lasts for a long time, while the soft foam rubber and black rubber seal ensure durability and long-lasting performance.

Product Details

Rubber seals are a type of sealing device that is used to prevent the passage of matter or air. They are made from a variety of materials, including natural rubber, synthetic rubber, and silicone rubber. In this article, we will explore the different types of rubber seals and their properties.

One of the most common types of rubber seals is the neoprene rubber seal. Neoprene rubber is a type of synthetic rubber that is widely used for its high temperature resistance and pressure resistance. These seals are typically used in applications that require high-temperature and high-pressure resistance, such as in the oil and gas industry.

Another type of rubber seal is the natural rubber seal. Natural rubber is a type of rubber that is derived from the latex of the rubber tree. These seals are known for their excellent flexibility and resilience, making them ideal for use in applications that require a high level of resilience and flexibility, such as in the automotive industry.

Each type of rubber seal has its own unique properties and applications. Natural rubber seals are typically used in applications that require flexibility and resilience, while neoprene rubber seals are commonly used in applications that require high-temperature resistance and pressure resistance. Silicone rubber seals, on the other hand, are known for their high temperature resistance and pressure resistance, making them ideal for use in extreme conditions.

In conclusion, there are several types of rubber seals available, each with its own unique properties and applications. Understanding the different types of rubber seals and their properties can help engineers and designers choose the appropriate seal for their specific needs.

EPDM, with metal core, Soft foam rubber, black rubber seal is a type of high-quality tire material that is widely used in various vehicles, especially those in the racing industry. This material is known for its excellent performance and long-lasting quality. In this article, we will explore the characteristics of EPDM, its benefits, and how it compares to other tire materials.

EPDM stands for Ethylene-Propylene-Diene Monomer. It is a type of rubber that is made from a polymer of ethylene and propylene, along with a small amount ofdiene monomer. EPDM rubber is known for its excellent heat resistance, ozone resistance, and chemical resistance. This material is commonly used in the production of tires for racing vehicles, as it is able to withstand the high temperatures and stresses of competition.

The metal core of an EPDM tire is an important component. It provides stability and strength to the tire, as well as resistance to rotation. The core is surrounded by soft foam rubber, which provides comfort and stability while riding. The black rubber seal on the outside of the tire provides a water-resistant finish and enhances the overall appearance of the tire.

EPDM tires are known for their high strength and durability. The EPDM material used in the core of the tire has a high tensile strength, making it able to withstand high pressures and stresses. The soft foam rubber surrounding the core adds comfort and stability, while the black rubber seal provides a water-resistant finish. This combination of materials ensures that the tire lasts for a long time and performs well under adverse conditions.

In terms of comfort, EPDM tires are often praised for their plush ride. The soft foam rubber provides a comfortable ride, reducing discomfort caused by harsh impacts and vibrations. This makes EPDM tires an excellent choice for drivers who demand a high level of comfort while driving.

One of the main benefits of EPDM tires is their improved grip. The black rubber seal on the outer surface of the tire provides improved traction and grip, making the tire more resistant to slippage and instability in adverse conditions. This is especially important for drivers who operate in extreme weather conditions, such as cold temperatures or high winds.

EPDM tires also have improved fuel efficiency compared to other tire materials. The reduced weight of the tire and the water-resistant finish ensure that the tire is more efficient and runs more smoothly, reducing operating costs.

In conclusion, EPDM, with metal core, Soft foam rubber, black rubber seal is a high-quality tire material that is widely used in the racing industry. It is known for its excellent performance and long-lasting quality. Its metal core provides stability and strength, while the soft foam rubber adds comfort and stability. The black rubber seal provides a water-resistant finish, enhancing the overall appearance of the tire. Overall, EPDM tires are an excellent choice for drivers who demand the highest level of performance and comfort.

Q1.Which kind of product do you produce?

Kingtom:Rubber injection parts,rubber compression parts and rubber extrusion parts,rubber-metal parts,plastic parts.

Q2.What information do you need for making price?

Kingtom:

1.2D/3D drawing,or samples photo with detail size.

2.Material And Material hardness

3.Detail quantity

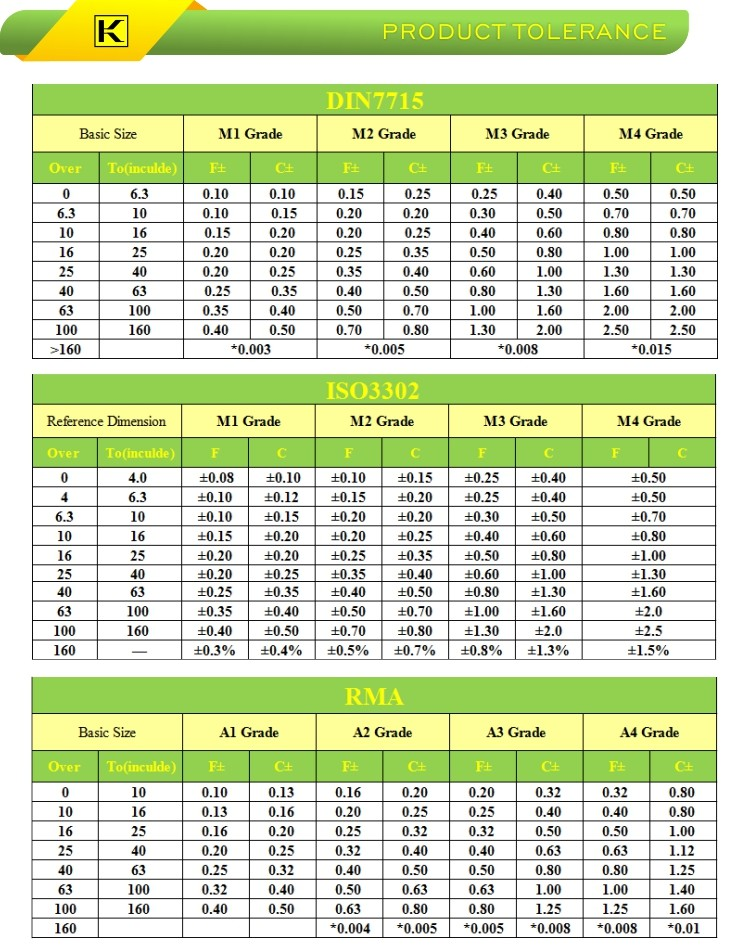

4.Your other requirements like tolerence,surface treatment.

5.Product usage environment

Q3.I don't have 3D drawing,how should i do ?

Kingtom:You can send one sample to us,then we can produce as your sample.

Q4:How to make sure the quality?

Kingtom:Check the samples before mass production.

There is the detail inspection report and goods photos before shipping.

Q5.Do you provide samples?

Kingtom:Yes,samples is free and you just pay the express cost.

Q6.How is the delivery time?

Kingtom:It usually takes 10-30days.It depends on the orders.