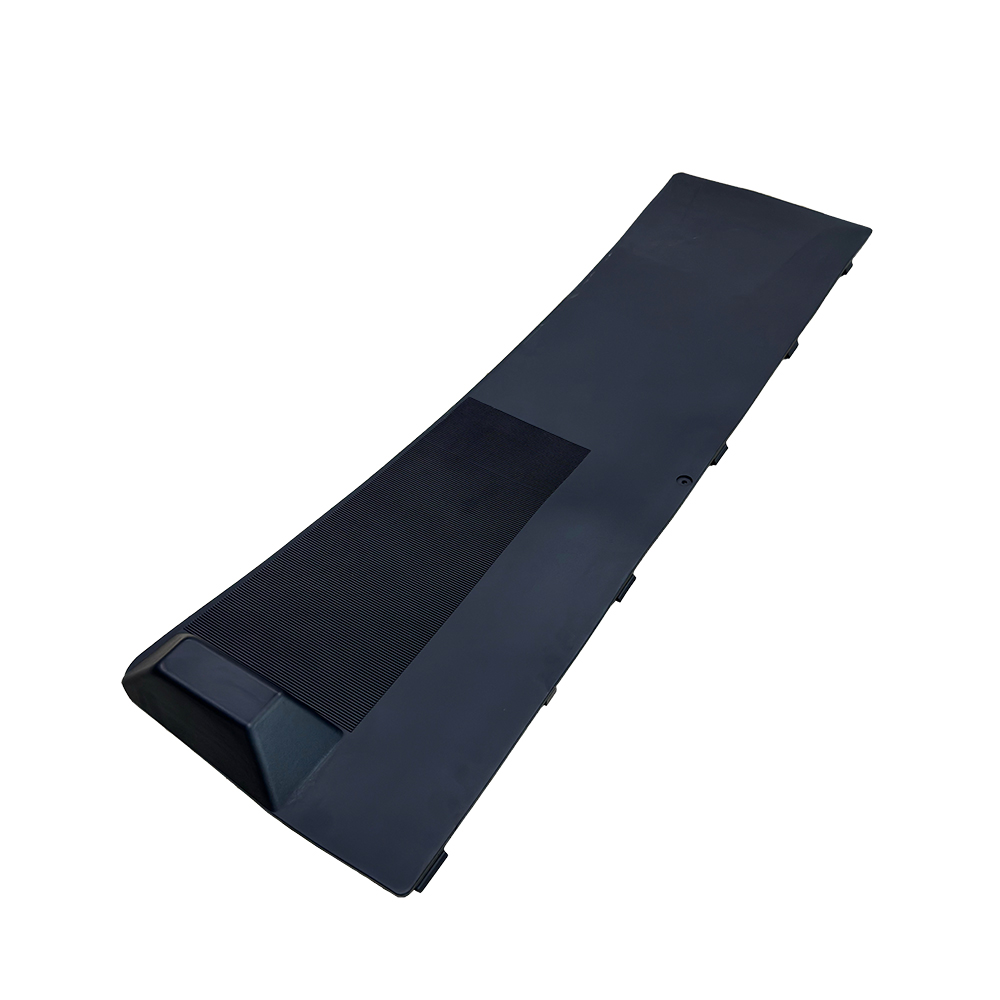

OEM/ODM Carousel Rubber Slat In The Airport

- Material:: SBR NBR or custom

- Size:: Custom

- Color:: Black or custom

- Application:: Airport

- Certifications:: IATF16949 ,ISO14001:2015,ROHS,CMC, etc

Overview

The Airport Carousel Rubber Slats have significantly enhanced the efficiency and quality of baggage handling services at the airport, serving as a crucial component in the seamless operation of airport activities. These slats are characterized by low noise levels, flame resistance, mildew resistance, durability against aging, and antistatic properties.

Product Description

Crafted with unmatched durability in mind, black rubber slats incorporated into airport conveyor belts undergo meticulous engineering to streamline luggage transportation and storage processes. These advanced slats expertly absorb vibrations generated by the operating scale plate, vastly improving the overall system’s performance. Furthermore, they integrate exclusive additives that encourage self-lubrication, minimizing friction and eliminating disruptive sounds, resulting in a seamless, silent operation that enriches the airport users’ experience.

Product Features

Material selection: The rubber sheets of airport baggage conveyor belts are usually made of materials such as NBR (nitrile rubber), PVC (polyvinyl chloride) or SBR (styrene butadiene rubber). Among them, NBR has good fireproof and anti-static properties; SBR has good wear resistance and relatively low cost.

Performance advantages: Rubber sheets have the characteristics of low noise, impact resistance, wear resistance, fire resistance, mildew resistance, anti-aging and anti-static. In addition, these rubber sheets are added with self-lubricating additives to reduce friction and eliminate abnormal sounds.

Customized service: Support OEM/ODM customization, customers can provide 3D drawings or samples according to needs, and manufacturers can produce according to requirements.

Advantages

Quality assurance: Manufacturers provide sample inspection services to ensure that product quality meets requirements.

Environmental protection and sustainability: Some manufacturers focus on environmentally friendly production, and their products meet the requirements of sustainable development.

Our company have below sizes for your reference.You also can provide us 3D drawings to custom.

Experience: More than 20 years experience in rubber OEM production

Shape: According to customer’s drawing

Package: PE bags, Cartons,Pallet

Payment Terms: T/T,L/C and so on.

Sample time: 25-30 days

Shipment Way: Vessel,Air,Express etc.

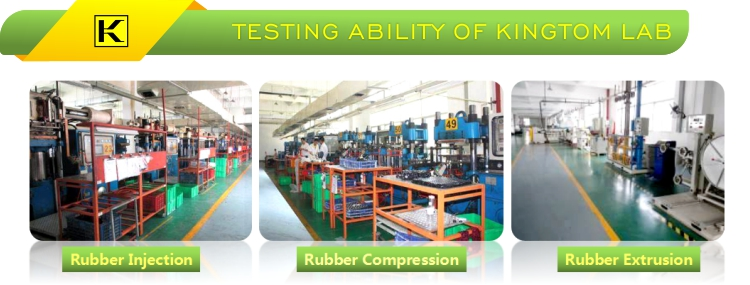

Q1.Which kind of product do you produce?

Kingtom:Rubber injection parts,rubber compression parts and rubber extrusion parts,rubber-metal parts,plastic parts.

Q2.What information do you need for making price?

Kingtom:1.2D/3D drawing,or samples photo with detail size.

2.Material And Material hardness

3.Detail quantity

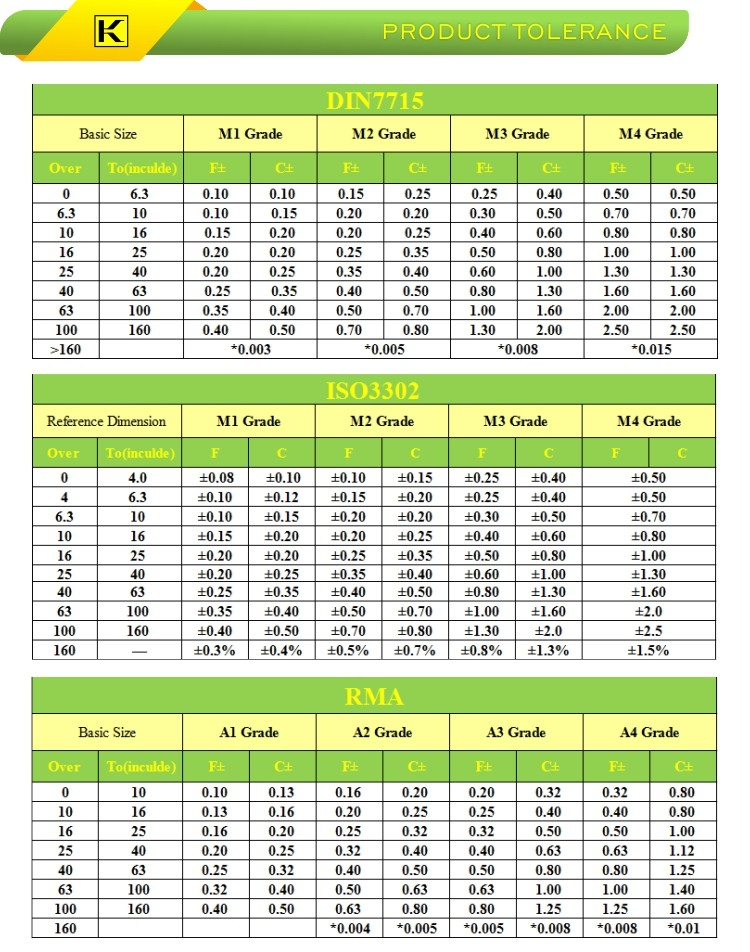

4.Your other requirements like tolerence,surface treatment.

5.Product usage environment

Q3.I don’t have 3D drawing,how should i do ?

Kingtom:You can send one sample to us,then we can produce as your sample.

Q4:How to make sure the quality?

Kingtom:Check the samples before mass production.

There is the detail inspection report and goods photos before shipping.

Q5.Do you provide samples?

Kingtom:Yes,samples is free and you just pay the express cost.

Q6.How is the delivery time?

Kingtom:It usually takes 10-30days.It depends on the orders.